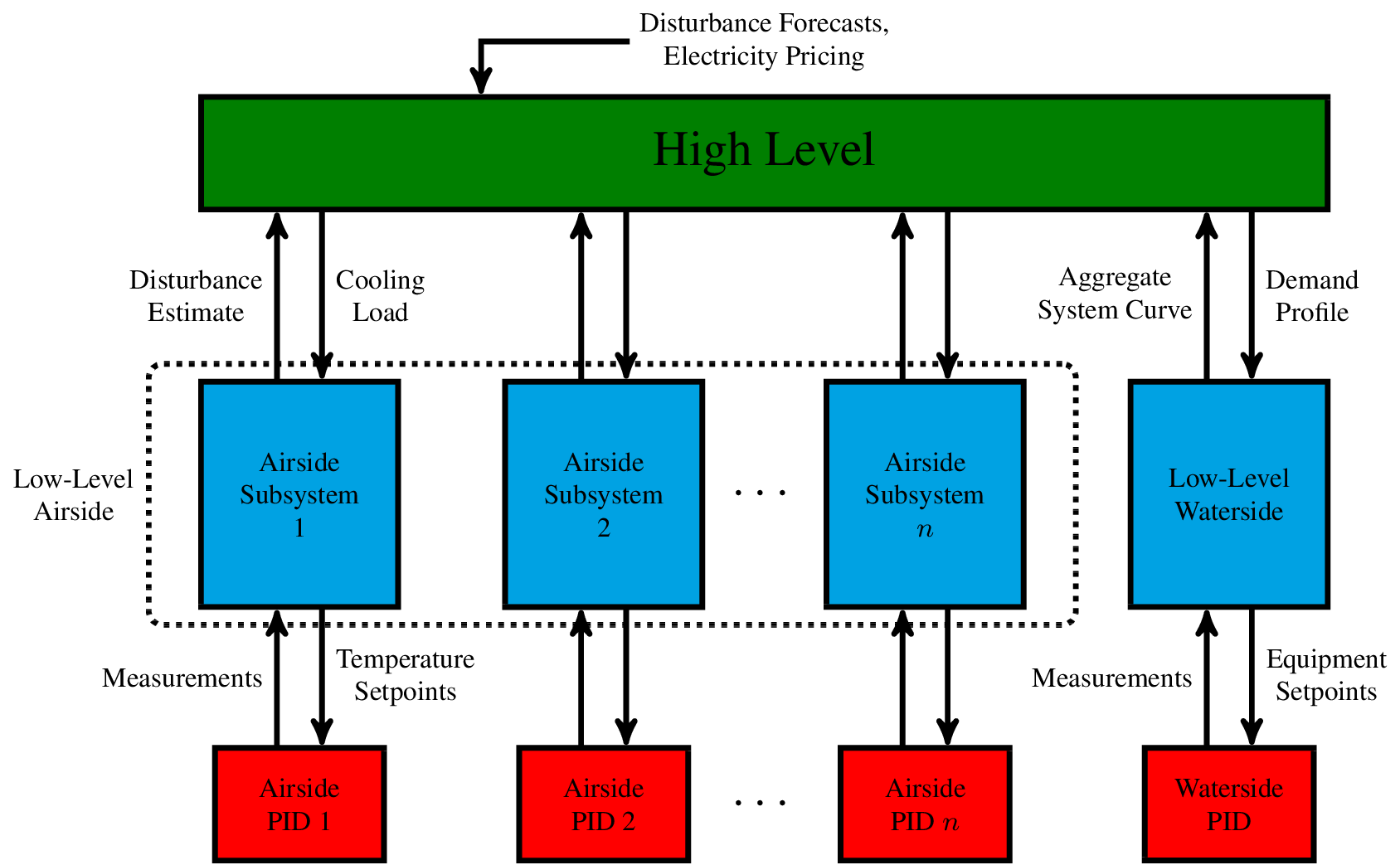

DecompositionThe aim of the release is to encourage researchers in the area of HVAC control to propose alternative control systems and to provide a common basis for performance evaluation of these strategies on a large-scale industrially relevant system. Here, we simulate the performance of one such control system that relies on a hierarchical two-layer structure.Control SystemWe consider the two-layer hierarchical control system presented in Patel, Rawlings, Wenzel and Turney (2016).

This structure relies on using a high-level problem with aggregate models of the airside and waterside systems to perform a plant-wide economic optimization. The solution is then sent to low-level airside and waterside controllers that use more detailed models to compute the dispatched trajectories which meet the constraints. The low-level controllers follow the load computed in the high-level problem as closely as possible. One low-level airside controller is used per building, to ensure the problem can be solved quickly online. Within the optimization problem, the following simplifications are made in the low-level problems:

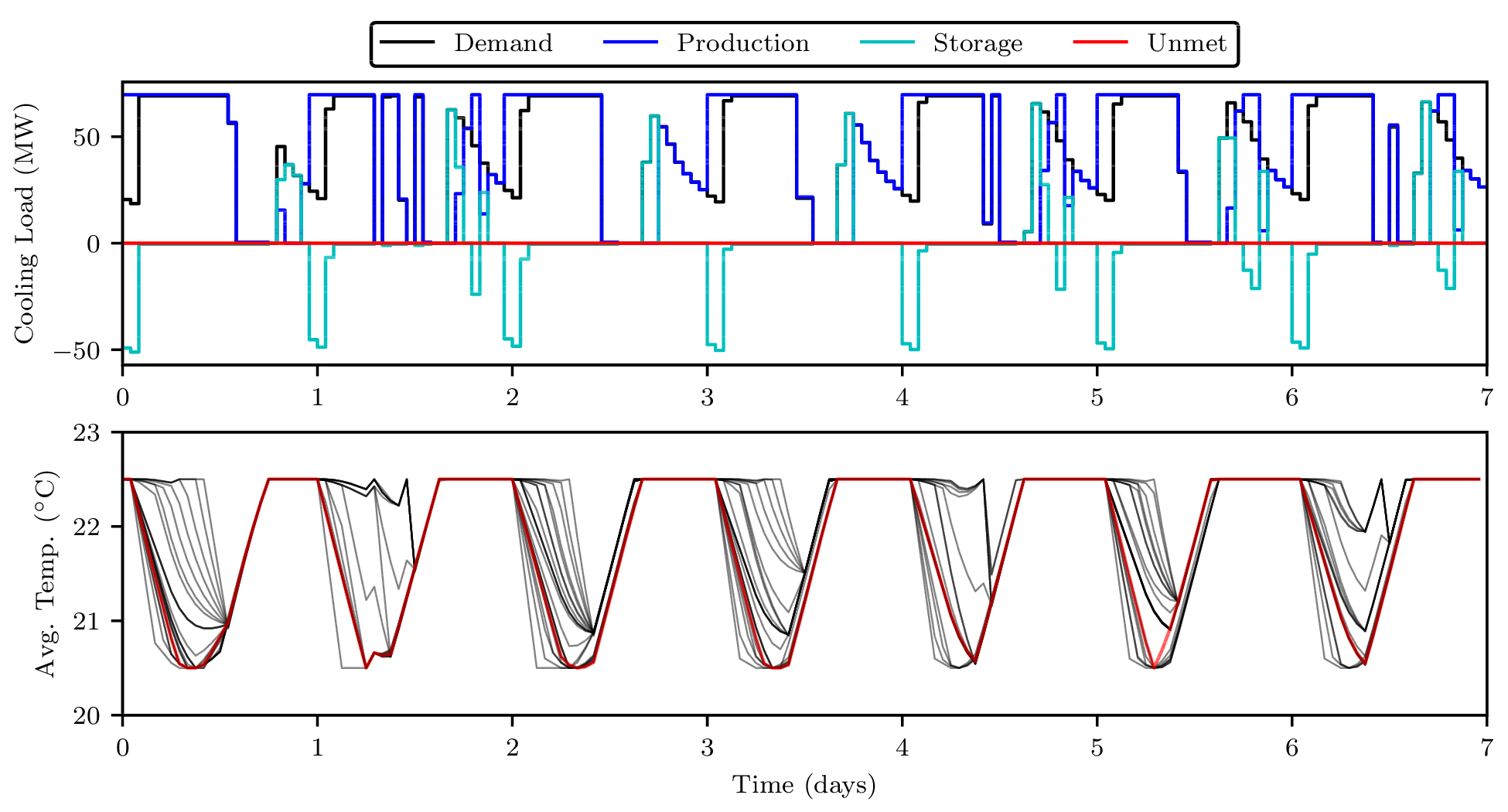

ResultsThis control architecture was applied to the case study system. The results from the high-level optimization are shown below. The high-level problem decides to use a combination of active and passive thermal energy storage to shift the power load from peak hours to off-peak hours. One particular building is highlighted in red.

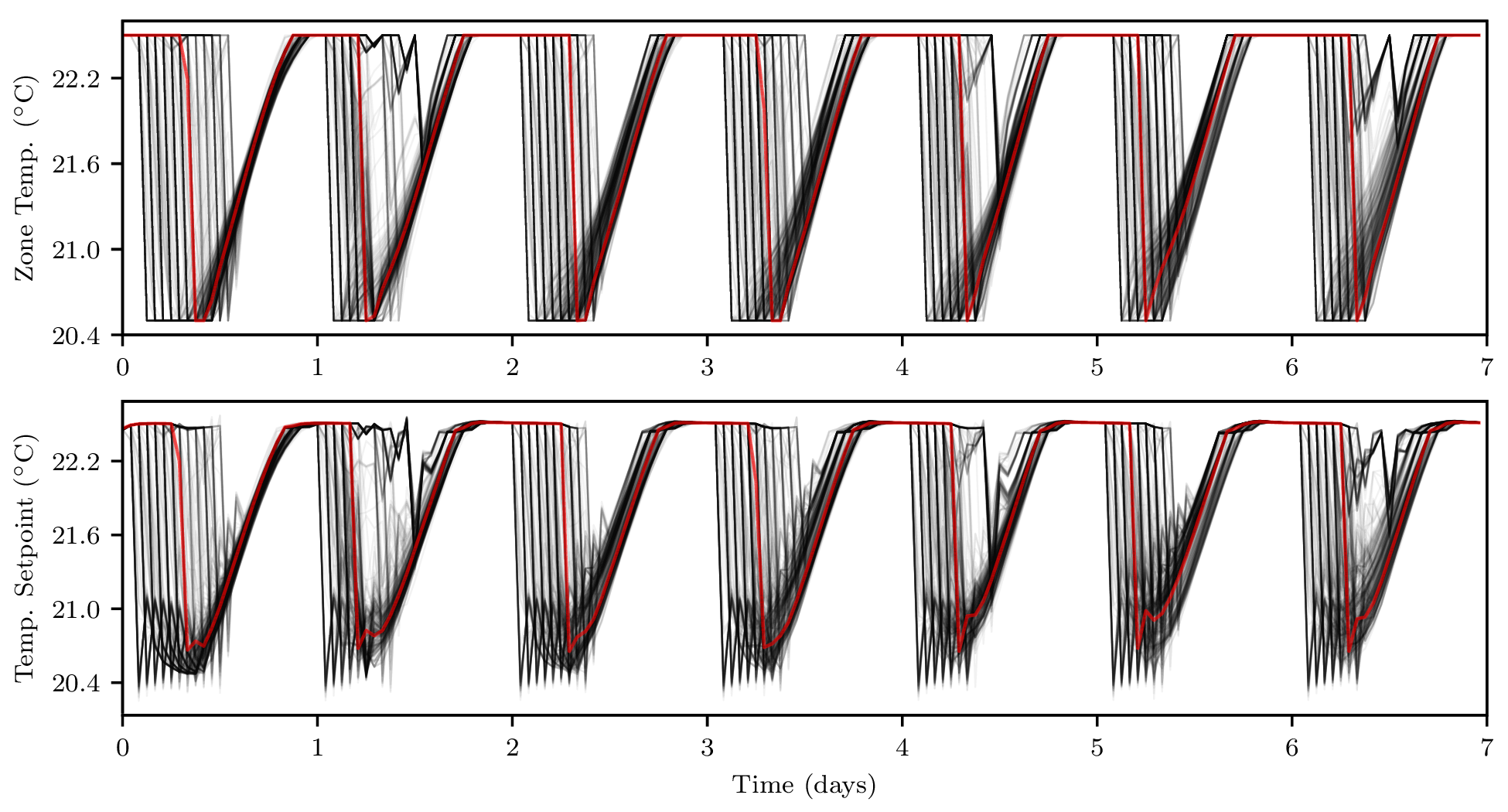

These load profiles are sent to the low-level problems. The low-level airside results for all 500 zones, including the zone temperature setpoints dispatched to the system, are plotted below. One particular zone is highlighted in red.

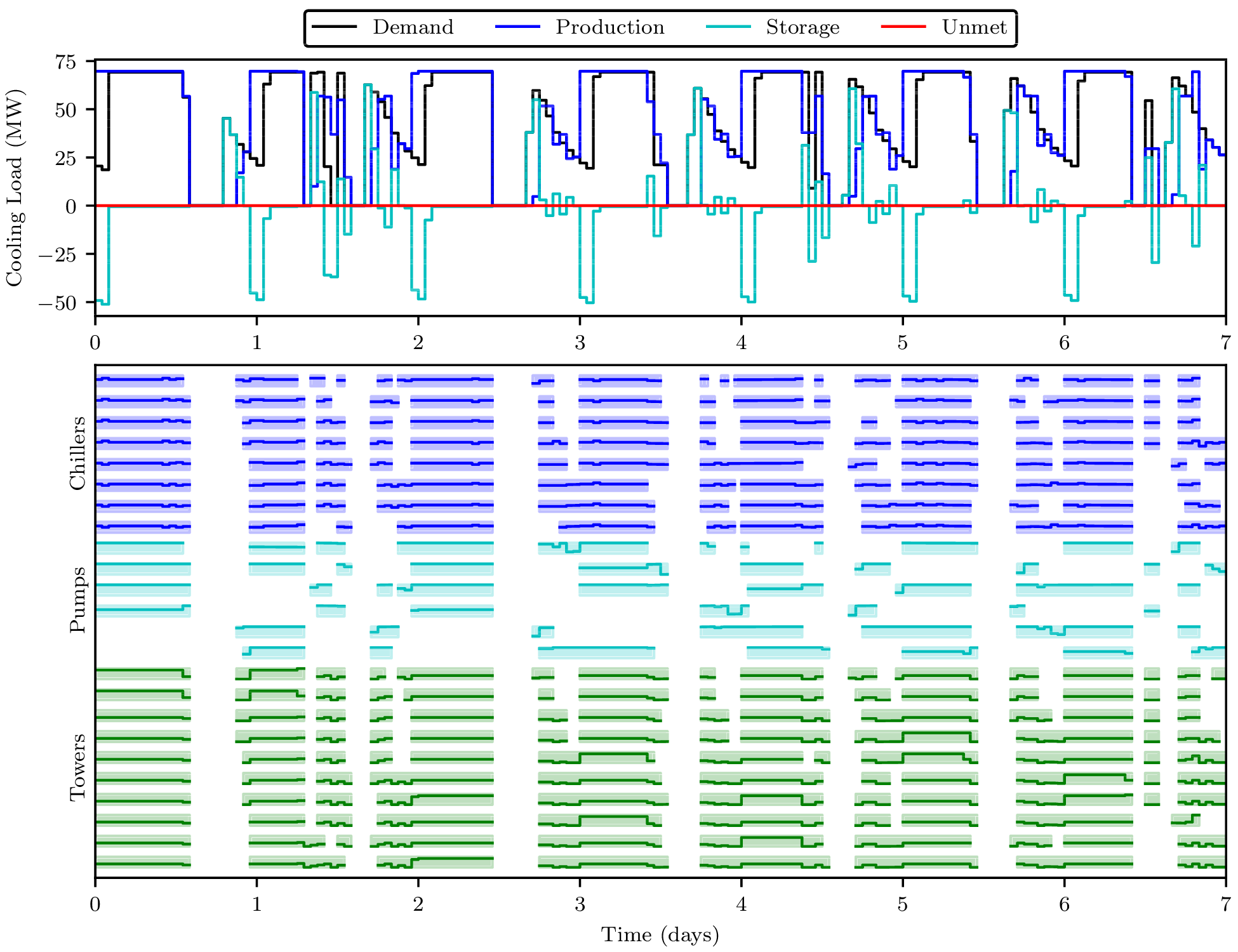

The equipment operation schedule computed by the low-level waterside optimization to meet the load from the high-level problem is display below.

Load shifting is able to reduce costs by purchasing more power when prices are lower during the early morning hours and charging the active storage tank as well as precooling buildings and purchasing less power when prices are more expensive during the peak hours by discharging the storage tank and letting the zones heat up to the upper bound of the comfort zones. As a result, the total cost for this control policy is $78,689. For comparison, the cost without load shifting is $94,878, hence using optimization with thermal energy storage results in 17% cost savings. |